What are Lab Grown Loose Diamonds?

Laboratory-grown loose diamonds, also known as synthetic diamonds, man-made diamonds or chemical diamonds, are the process of forming diamond crystals on man-made crystal seeds by using chemicals under high temperature and high pressure conditions that simulate the natural environment in the laboratory.

Compared to natural diamonds, lab-grown loose diamonds have the following characteristics:

- High purity: The manufacturing process of laboratory-grown loose diamonds is more precisely controlled, so loose diamonds are usually higher in purity than natural diamonds.

- Controllable color: The color of natural diamonds is controlled by the geological environment and minerals, while the color of laboratory-grown loose diamonds can be controlled by adding different chemical elements to obtain a more pure and vivid color.

- Inexpensive: Because lab-grown loose diamonds are man-made, they are much less expensive than natural diamonds and can be used as an alternative.

|

item

|

lab grown diamond

|

|

Brand Name

|

Hydray

|

|

Place of Origin

|

China

|

|

zhengzhou

|

|

|

Type

|

Synthetic (lab created)

|

|

Carat Weight

|

0.05-2carat

|

|

Certificates

|

IGI

|

|

Shape

|

Round Brilliant Cut

|

|

Fancy Diamond Color

|

White

|

|

White Diamond Color

|

D

|

|

Diamond Clarity

|

FL

|

|

Optical Special effect

|

Color Play or Fire

|

|

Application

|

Jewerly Making

|

|

Material

|

diamond

|

|

Diamond Cut

|

Excellent

|

|

Hardness

|

10

|

|

Customization

|

Support

|

|

Way of selling

|

diamond factory direct sale

|

|

Shape

|

round, emerald cut, oval, pear,princess and so on

|

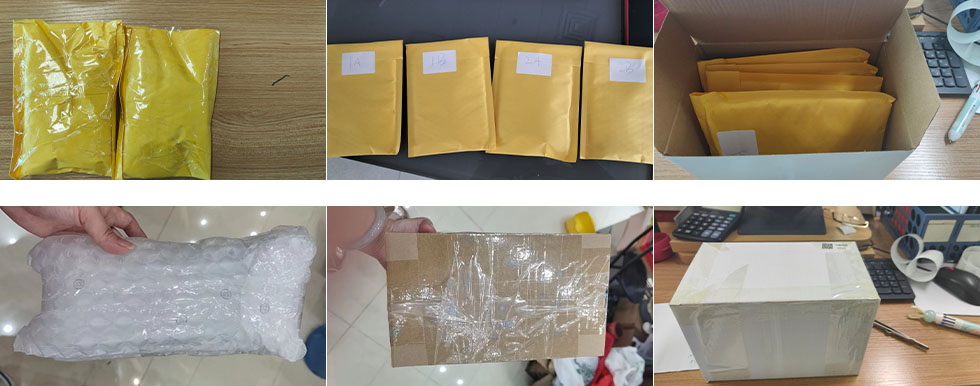

Product Display

How Lab-Grown Loose Diamonds Are Made into Jewelry

- Screening loose diamonds: Classifying loose diamonds according to characteristics such as size, color, shape, etc., for the next step of processing.

- Cutting Loose Diamonds: Loose diamonds are precisely cut and processed using a diamond cutting machine to create diamonds of different shapes and sizes. Cutting a diamond requires expertise and experience to ensure the best optical performance and aesthetics of the cut diamond.

- Hand polishing: After machine cutting, there are still some burrs or irregular parts on the surface of diamonds, which need to be polished by hand to make the surface smooth and clean. The grinding process requires the use of diamond grinding wheels or other grinding tools.

- Inlay: Inlay polished diamonds into jewelry. Jewelry can be items of different types and shapes such as rings, necklaces, earrings, etc. The setting process requires great care and precision to ensure that the diamond is securely set in the jewelry and is able to perform at its best optically.

- Polishing: Finally, polish the inlaid ornaments to make the surface smoother and brighter. Polishing requires the use of high-tech tools and techniques to ensure a flawless finish.